Our Penetrant Formula (Yellow Capsule #1004) is comprised of synthetic oil, organic thickeners, wetting agents, extreme pressure additives and corrosion inhibitors. It is designed to migrate between mating metals parts and loosen friction points. This assures penetration into moving mechanisms to assure excellent performance of these mechanisms. This penetrating property allows dried out, corroded surfaces to function like new after our penetrant has been applied. The penetration of this material into the mechanisms will begin immediately upon application. For better results, allow the penetrant to work into the mechanism for 2-5 minutes before operating it.

Our Penetrant Formula (Yellow Capsule #1004) is comprised of synthetic oil, organic thickeners, wetting agents, extreme pressure additives and corrosion inhibitors. It is designed to migrate between mating metals parts and loosen friction points. This assures penetration into moving mechanisms to assure excellent performance of these mechanisms. This penetrating property allows dried out, corroded surfaces to function like new after our penetrant has been applied. The penetration of this material into the mechanisms will begin immediately upon application. For better results, allow the penetrant to work into the mechanism for 2-5 minutes before operating it.

A study conducted by Entergy demonstrated that our system reduces the pull force needed to open MOAB (Manually Operated Air Brake Switches) systems resulting in a 22% reduction in force required to open and 37% reduction in force required to close the switches helping to avoid work-related injuries.

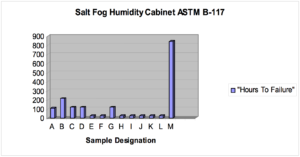

This product yields excellent corrosion protection. Per the chart below, our synthetic penetrant provides 840 hours of rust protection in ASTM B-117 (Salt Fog Humidity Chamber). In Coastal areas which are under constant attack from salt and most often extreme sun, this material loosens frozen mechanisms and restores operability of corroded mechanism. It has a functional temperature range from -65 deg. F to 300 Deg F. It will not become gummy, tacky, or dry out over time. Regular application assures that mechanism operate effectively throughout their designed lifetime.

The capsules that contain Results Lubricating’s penetrant are bio-degradable and will dissolve in 4-5 weeks if left outside. This assumes normal precipitation and sun exposure.

Do not allow the capsule to be stored in a humid environment or be exposed to temperatures over 110 deg. F for extended periods of time as degredation of the capsules will occur. Store the capsules in a cool, dry environment.

FOR USE ON:

- Hinges

- Pivots-Points

- Fasteners

- Universal Joints

- Gang Operated Switch Junctions • Frozen Switches

TECHNICAL DATA INFORMATION

|

TEST |

ASTM Method |

Typical Test Results |

|

Operating Range, Min °F, Max °F |

-65 °F to 300 °F |

|

|

Salt Fog Chamber Test |

ASTM B-117 |

+840 Hrs |

|

Specific Gravity |

ASTM D-1298 |

.80% |

|

Flash Point |

ASTM D-92 |

>200°F |

|

Solubility in Water |

Negligible |

|

|

Reactivity in Water |

Negligible |

|

|

Vapor Pressure |

1 mm @ 20°C |

Corrosion Test Information

In the following chart, 11 competitive products were chosen for testing against Results Lubricating Penetrant, testing was conducted by an independent laboratory. Testing methodology was ASTM B-117 salt fog corrosion. Three carbon steel panels of each candidate were sand blasted, coated with candidate’s product, exposed to synthetic seawater salt fog, 100% humidity, and monitored for rust formation. Upon detection of corrosion, test was ended for that candidate and total exposure time was logged. Certifications of testing results are available upon customer’s written request.

|

SAMPLE |

FAILURE/HOURS |

PRODUCT NAME AS TESTED |

|

A |

110 |

B’Laster Corrosion Stop Water Resistant Spray Grease |

|

B |

216 |

Results Lubricating Grease formula (Red Capsule) |

|

C |

120 |

WD-40 |

|

D |

120 |

Service Spring Multi Purpose |

|

E |

24 |

National Heavy Duty Garage Door/Operator Lubricant |

|

F |

24 |

Garage Door Lubricant GDL-100 |

|

G |

120 |

Liquid Wrench Lubricating Oil |

|

H |

24 |

Door1 Garage Door Super Lube |

|

I |

24 |

Denco Foamy Garage Door & Operator Super Lube |

|

J |

24 |

Denco Garage Door Lubricant Ultra Gel |

|

K |

24 |

Famous B’Laster – The Dry Lube |

|

L |

24 |

PrimeFlo Silicone Lubricant |

|

M |

840 |

Results Lubricating Penetrant Formula (Yellow Capsule) |